Galvanization is the process of coating steel tubes with zinc to prevent rust and corrosion. For padel courts, where metal tubes face constant outdoor exposure (rain, humidity, salt), this coating is make-or-break for lifespan.

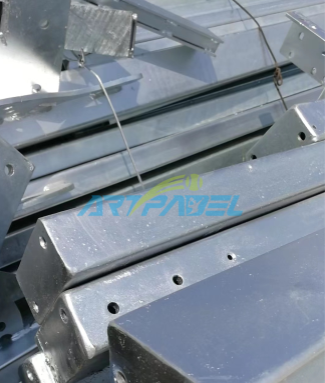

Artpadel exclusively uses hot-dip galvanization for its metal tubes—including 100mm×100mm×3mm corner pillars and 100mm×50mm×3mm supports—dipping entire tubes into 500°C liquid zinc to form a thick, uniform protective layer that covers every detail.

Different Galvanization Processes: A Critical Comparison:

About Durability

Hot-dip galvanization: Ideal—handles outdoor harshness, lasts decades.

Electro-Galvanization: Not suitable—rusts in 1–2 years outdoors

Why It Matters for Padel Players & Investors?

- For players: A galvanized frame means a stable, safe court. No loose pillars, weakened supports, or rust flakes that could cause trips or equipment damage.

- For investors: Hot-dip galvanization cuts long-term costs (no repeated repairs) and boosts the court’s value. Art Padel backs its galvanized structures with a 4-year warranty—a testament to its reliability.

Contact Art Padel now:

Tel: +86 532 68978909

WhatsApp/Wechat/Tel: +86 19050566530

Email: art02@artpadel.com

Web: www.artpadel.com